当前位置:Index>Products>iDream Series

• The EtherCAT bus enables real-time data sharing among the computer controller, servo drives, and servo motor.

• This tri-integrated system ensures more precise control of the injection molding process.

• The iDream computer control system achieves a control cycle of 250μs with a mechanical repeat control accuracy of 0.01mm.

• It supports networked expansion capabilities, facilitating data collection and analysis of customer, product, and equipment operation status.

• The high-performance, high-response, low-inertia injection motor provides substantial instantaneous overload torque, meeting the demands of high-speed injection processes.

• The panel features a vertical screen design with smooth lines, offering an aesthetically pleasing and elegant appearance.

• It is equipped with abundant I/O resources, communication buses, and analog interfaces, meeting the hardware configuration requirements for high-speed and all-electric machines.

• The system adopts a common DC bus drive architecture, integrating a unified rectifier unit with multiple inverter modules. It supports parallel installation for space-efficient integration.

• EtherCAT high-speed bus comes standard, meeting the demands of real-time, high-volume data exchange between external controllers and the servo system, as well as within the system itself.

• Dual-channel STO (Safe Torque Off) safety functions are incorporated, with internal bus-based networked monitoring capabilities.

• Industry-leading IPM (Interior Permanent Magnet) electromagnetic technology, ensuring non-demagnetization, low current requirement, and minimal temperature rise.

• Designed with 2.5 times overload torque capability, delivering high peak torque output.

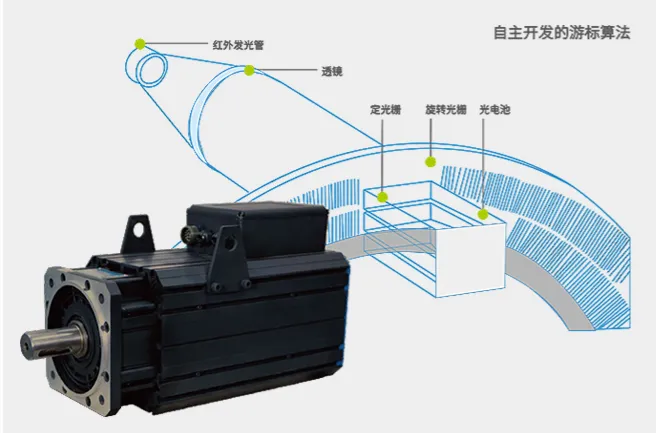

• Full motor series equipped with 23-bit encoders, achieving control precision up to 1/2²³.

• Unique anti-vibration encoder structure design, with vibration resistance up to 5G and protection rating of IP67.

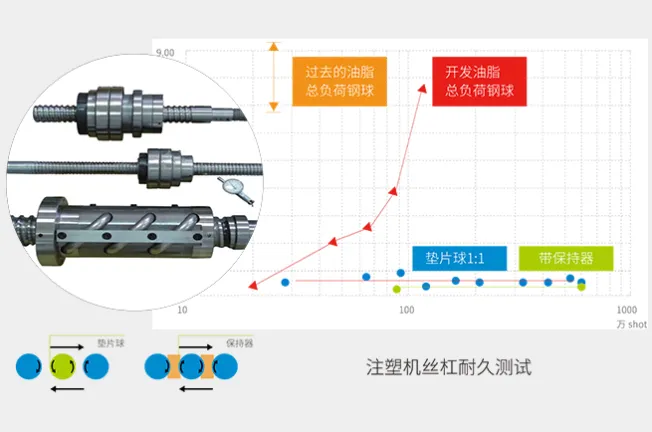

• High Reliability: The Line PBS(K) series ball screws incorporate ball spacers, specialized high-load materials, and an optimized groove curvature and contact angle design, collectively ensuring enhanced load capacity and extended service life.

• High-Speed Performance: For applications requiring continuous high-speed operation, the PBS(K) series employs a specially designed circulation mechanism and large lead specifications, enabling a maximum Dn value of up to 140,000 while maintaining load-bearing longevity.

400-080-1890

咨询热线手机站